Features

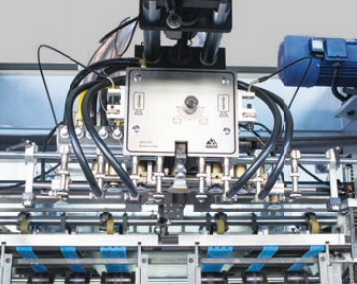

01/FEEDING UNIT

High precision feeding head which can smoothly running with thin paper and all kinds of cardboard in high speed. Equipped with gantry type preloading mechanism.Main and vice feeding platform working by turns to achieve |

02/CONVEYING UNIT

Vacuum conveying system which can ensure thin paper stable and precise conveying. Equipped with Taiwan push-and-pull dual purpose guide lay to make stable positioning in high speed running;conveying wheel quick adjusting mechanism which can ensure high working efficiency |

03/DIE CUTTING UNIT

Pressure regulating device adopts gapless ballscrew to make sure precise and stable pressure adjusting. Torque overload protection device. |

04/DIE CUTTING STEEL PLATE FINE-ADJUSTING DEVICE

Steel plate fine adjusting device which can revise the bottom die quickly |

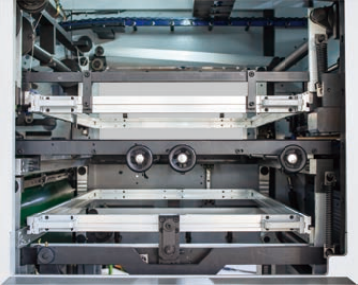

05/STRIPPING UNIT

Stripping unit adopts top,middle and bottom three frames design,collaboration curve is stable,precise and strong. Punch stripping and mould stripping can be adapted according to your product requirements.Stripping mould adopts central positioning method which can make sure convenient plate changing,precise positioning and stable running. |

06/SECONDARY STRIPPING UNIT

Secondary stripping device which can remove the waste margin away and send it out of the machine by the conveying belt. |

07/DELIVERY UNIT

Delivery unit adopts hair brush and back sucking system to make tidy paper stack. Delivery section can achieve non-stop running with pneumatic sampling device. Label mark counting function is available. |

08/GERMANY VACUUM PUMP

Adopt with Germany Becker vacuum pump which is stable and durable. |

Performance Characteristics |

TCut 106 Pro automatic diecutter is a key equipment for die-cutting, creasing and stripping of paper boxes, cartons, trademarks and other paper packaging and decoration products. This machine adopts unique transmission mechanism design such as high-precision intermittent mechanism, pneumatic lock plate, pneumatic clutch, overload protection, electric pressure adjustment, and paper feeder. It runs at high speed and stability. At the same time, the machine is equipped with practical and reliable mechanisms such as pre-coded paper mechanism, auxiliary paper feeding mechanism, variable speed paper feeding mechanism, automatic auxiliary paper receiving mechanism, pneumatic sampling mechanism, automatic timing oil supply and lubrication, and main drive lubricant forced air cooling device.

The machine can give full play to its working efficiency during use. The upper cleaning waste frame has a large lifting space and is more ergonomic, which effectively improves the work efficiency of the operator in the middle frame when installing needles. The electrical components and transmission components of this machine adopt internationally renowned brands to ensure die-cutting accuracy and operational reliability during use.

The electrical control system uses PLC and electronic cams to monitor and display the operation of the whole machine, which makes the machine fault diagnosis extremely convenient. The HMI monitoring and display system is adopted, which has the functions of providing operation instructions, fault point detection and display troubleshooting prompts. The electrical box is cooled by industrial air-conditioning, and the electrical components can operate continuously and stably at a constant temperature.

Specification |

Model | TCut 106 Pro |

Max. Sheet Size | 1060x760mm |

Min. Sheet Size | 390x280mm |

Min. Front Margin | 8~17 |

Max. Die Cutting Size | 1055x750mm |

Max. Die Cutting Pressure | 300Tons |

Sheet Grammage | 80 ~ 2000g/m2 |

Max. Die Cutting Speed | 8500 sheet/h |

Max. Height of Feeding Pile | 1400mm |

Max. Height of Delivery Pile | 1250mm |

Die Cutting Precision | ±0.075mm |

Main Motor | 11 Kw |

Total Power | 18 Kw |

Machine Weight | 19.3Tons |

Dimension (L*W*H) mm | 8028*4195*2386 |

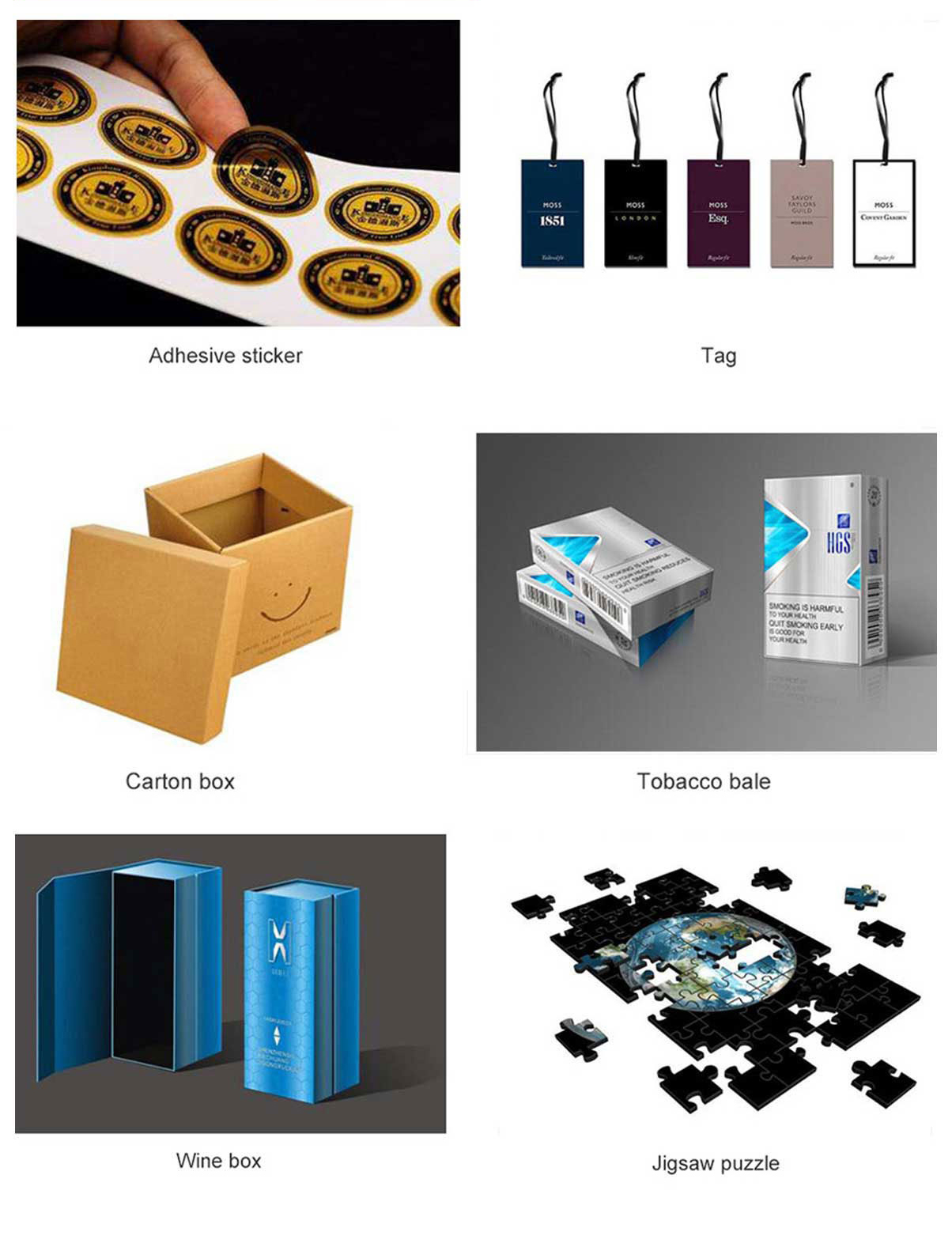

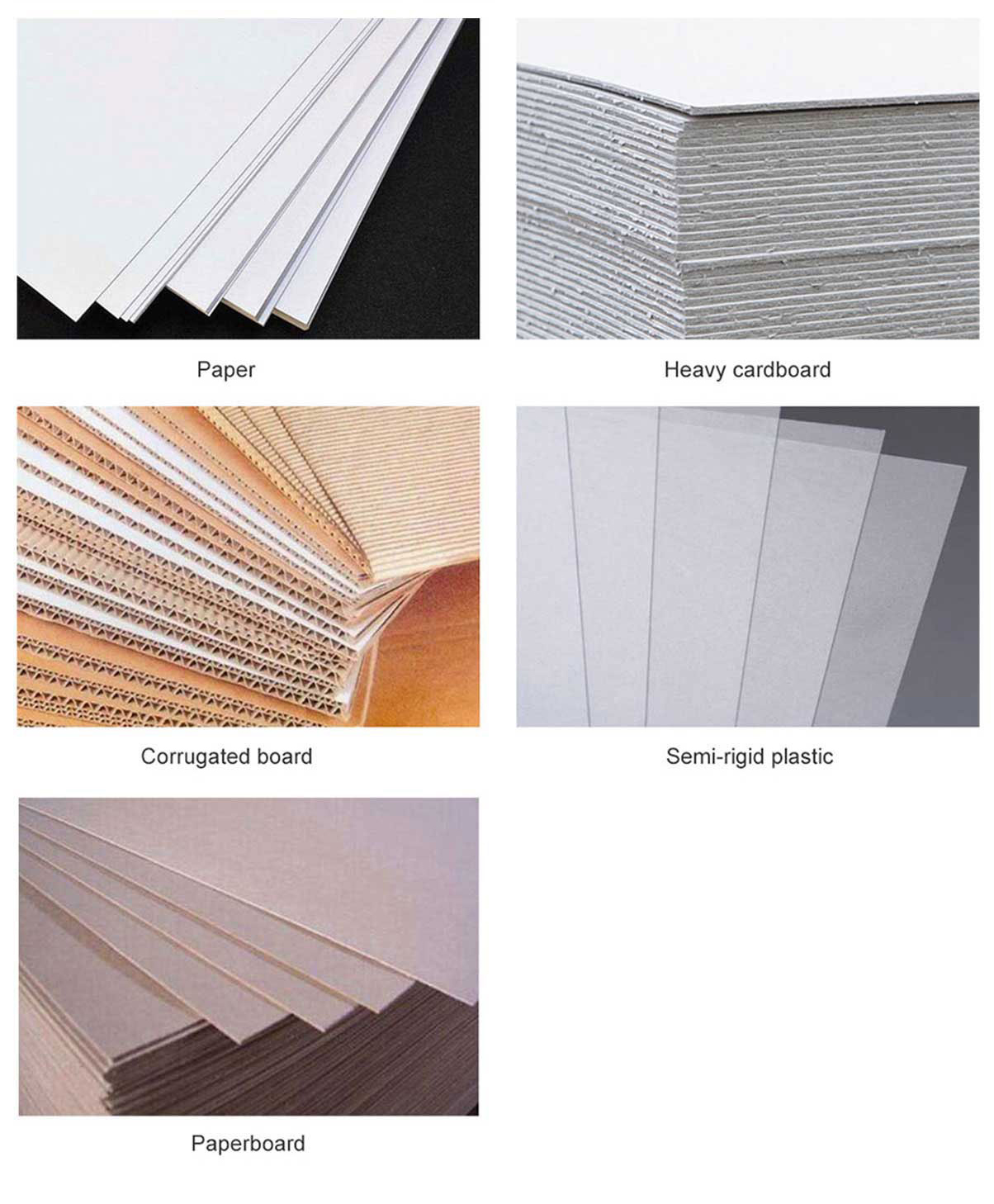

Application materials |

Application |