Features

360°Stop the rotating cylinder, super high printing accuracy;

LCD man-machine dialogue interface;

4-9mm adjustable network (screen distance between screen and drum);

Pull-out screen frame makes it easier to check the paper feeding status and clean the screen;

PLC controls the centralized lubrication oiler to ensure the lubrication of the transmission part, reduce the vulnerable parts of key components and extend the service life;

Photoelectricity monitors the status of empty sheets and crooked sheets during the printing process, effectively reducing the scrap rate;

The roller receives paper accurately, and the bite is small;

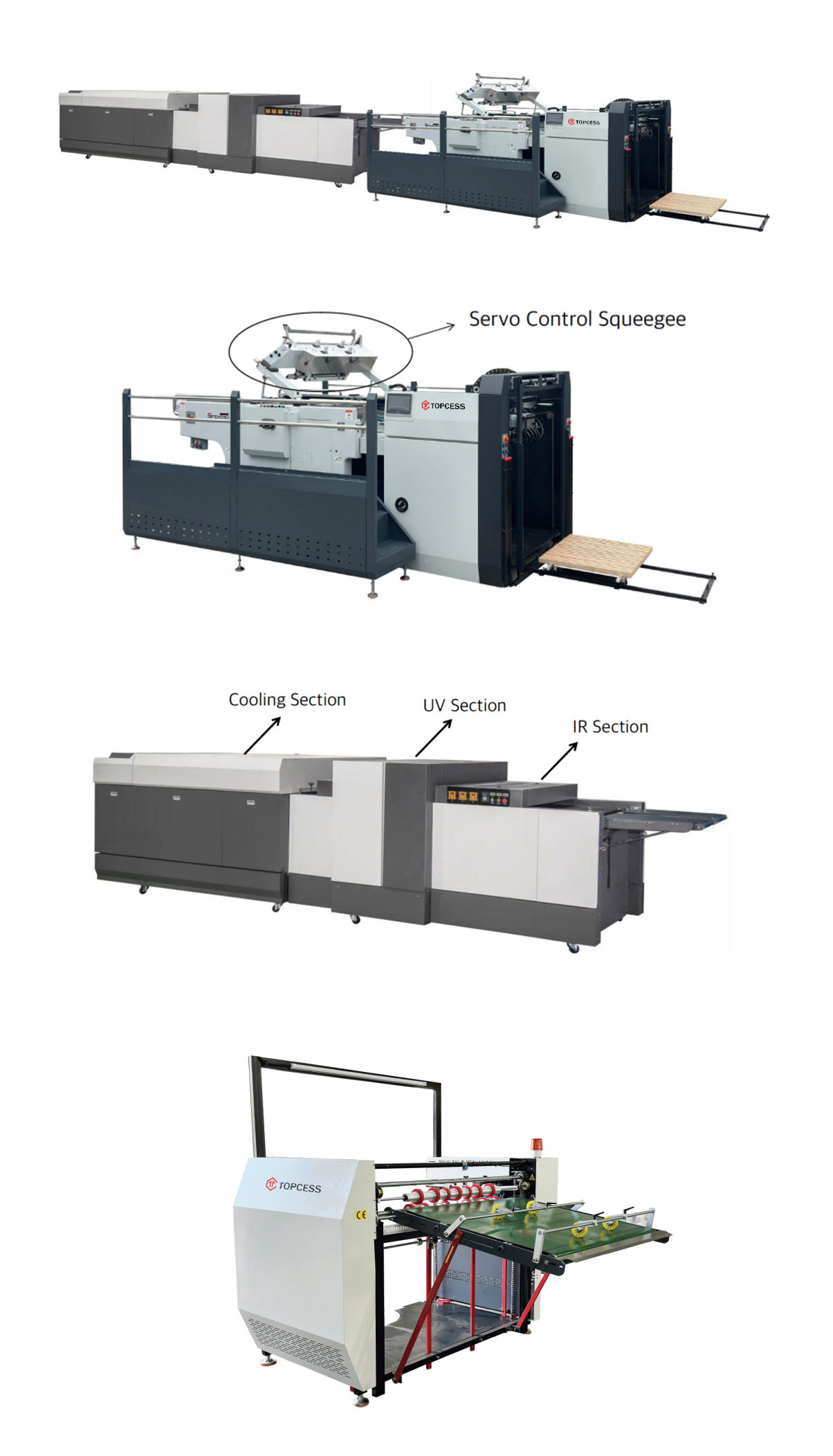

Pneumatic screen frame clamping device and auxiliary pressure holding device of squeegee;

Automatic ink tray device after shutdown;

Unique non-stop adjustable push/pull gauge design.

Specification |

Model | TS 105 |

Max.Sheet Size | 1060mmx760mm |

Min.Sheet Size | 450mmx350mm |

Max.Print Size | 1050mmx740mm |

Sheet Thickness | 90(g/m²)--420(g/m2) |

Frame Size | 1300mmx1170mm |

Print Speed | 800-4000iph |

Registration | ±0.05mm |

Gripper | =10mm |

Dust Remove Device (patented product) | (Optional) |

Squeegee Auto Pressure Device(Servo) | (Optional) |

Side Lay Auto Positon System(Servo) | (Optional) |

Anti-static Remove Device | (Optional) |

Photoelectric Double Sheet Detect Funtion | Ultrasonic Detector |

Sheet Pressure Delivery | Press Wheel/Glass Ball (Optional) |

Photoelectric Senor Detector | Sheet not in postion ,No Print |

Single/successive Sheet Feeding | Single sheet feeding with buffer |