Features

Feeding Unit Featuring independent motor drive with variable frequency speed control, it links proportionally with the main machine speed to stably and effectively maintain paper spacing. The feed knife rack and side guide plates are pneumatically adjustable for quick setup, while the paper support frame incorporates a powerful vibration motor to enhance smooth paper feeding. |

Register Effectively corrects misalignment of cartons after ejection, ensuring every carton with varying positional errors is positively registered at the pull gauge unit. This enables precise subsequent creasing/folding operations. The pull gauge can be selectively engaged on the left or right side according to carton structure. |

Folding-back Unit The long-span three-plate folding mechanism ensures cartons achieve a 180° fold at the first crease line and a 135° fold at the third crease line, facilitating effortless expansion during product loading. Featuring segmented upper pressure plates with left-right sectional design, it offers telescopic adjustment per production requirements, while providing convenient access for installing special carton configuration attachments. |

Lock Bottom Featuring a triple-plate conveyor system with modular segmented upper pressure plates, this design effectively handles production of non-standard carton configurations. Pre-installed mounting points allow for optional rear hook additions, while bottom hook attachments offer simplified installation and operation. |

Gluing Unit Equipped with dual mechanical glue pots (left/right sets) featuring specialized anti-sling design for glue containment at high speeds. The units disassemble effortlessly for simplified cleaning and maintenance. For bottom-hook applications, non-standard cartons, or small box formats, an optional electronic spray adhesive system is available. |

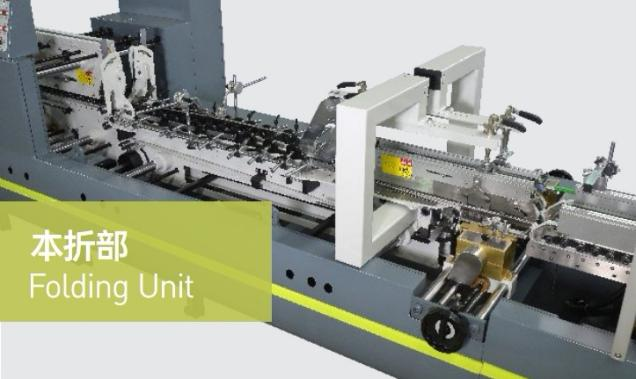

Folding Unit Rigid folding blades fixed to independent plates deliver powerful and stable product formation. The lateral folding belts allow micro speed adjustment on each side, enhancing folding precision. With specially designed telescopic belt mechanisms, the folding belt positions can be extended according to product requirements without belt re-tensioning, simplifying positioning adjustments. |

Trombone Featuring independent motor-driven upper and lower belt tiers (four sets total), the laterally telescoping belts travel on linear guides to automatically adjust length based on carton dimension. Equipped with photo-electric counting and pneumatic cylinder-activated marking functions, the continuous automatic stacking system ensures neat carton transfer to the conveying section. |

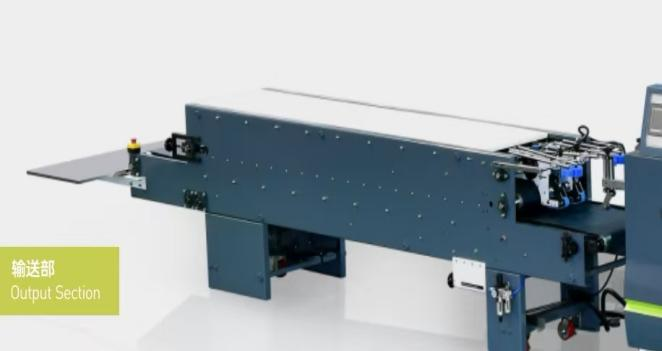

Output Section Independent frequency conversion adjustment, with proportional speed linkage to the main unit; The upper and lower transmission of the conveyor belt adopts an active device to ensure synchronous operation of the belt. Equipped with an independent drive mechanism, it can individually increase or decrease speed to widen or narrow the gap between sheets. |

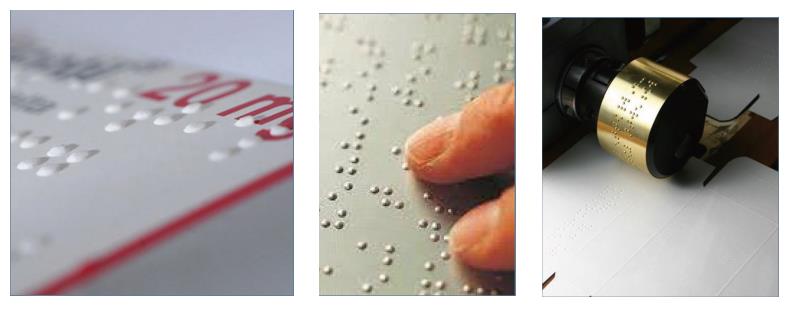

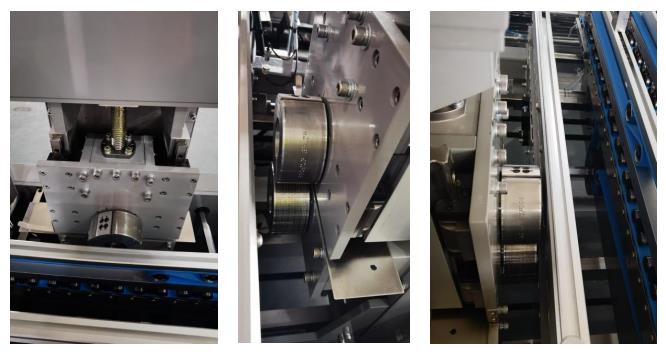

Braille Station The single-arm dual servo motor-driven upper and lower cam rotary embossing design allows digital adjustment of braille embossing pressure, ensuring precise and uniform pressure with simple replacement of braille convex-concave plates. |

Specifications |

Applicable Paper | White Cardboard (200-800 g/m²) |

Feeding Method | Positive Automatic Continuous Feeding |

Gluing Speed (MAX) | 350 m/min |

Braille Pre-Press Speed (MAX) | 200 m/min |

Braille Pre-Press Box Width | 1 to 5 lines |

Braille Pre-Press Position Accuracy | ±2 mm |

Braille Structure | Single-arm |

Braille Paper Compatibility | 200-400 g/m² Cardboard |

Braille Paper Surface Finish | Glazing or Laminating |

Box Production Width | 120-650 mm |

Mechanical Dimensions (L×W×H) | 15.5 × 1.7 × 1.5 m |

Adhesive Type | Solvent-based |

Total Weight (approx.) | 5.5 metric tons |

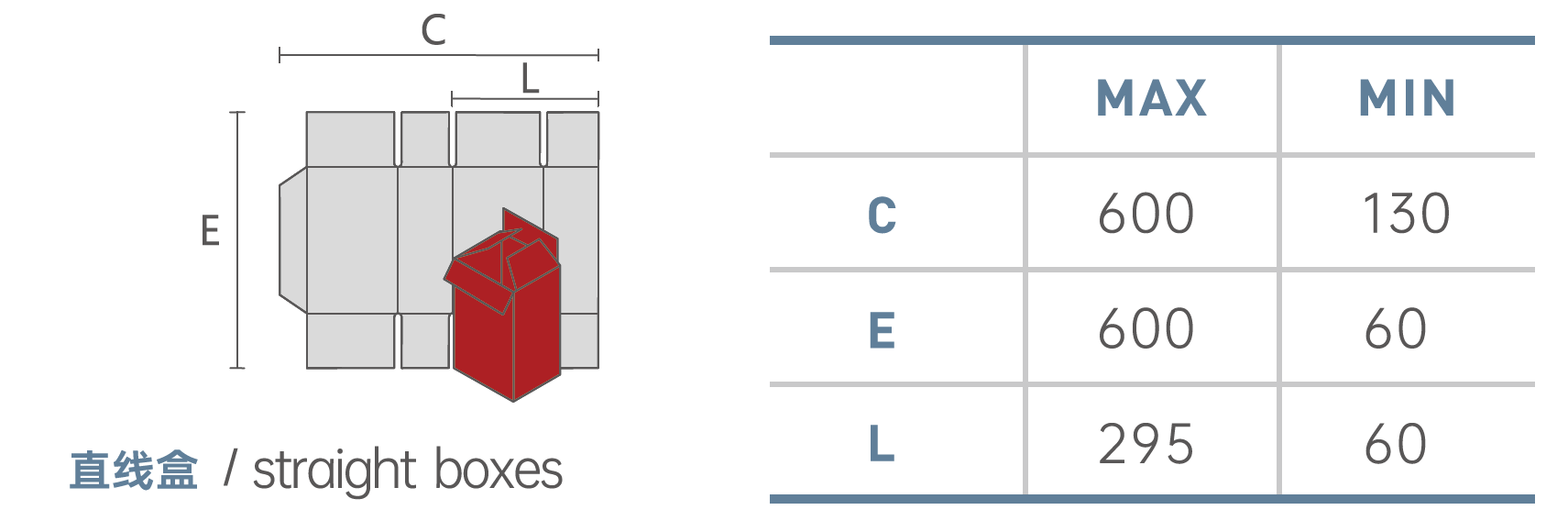

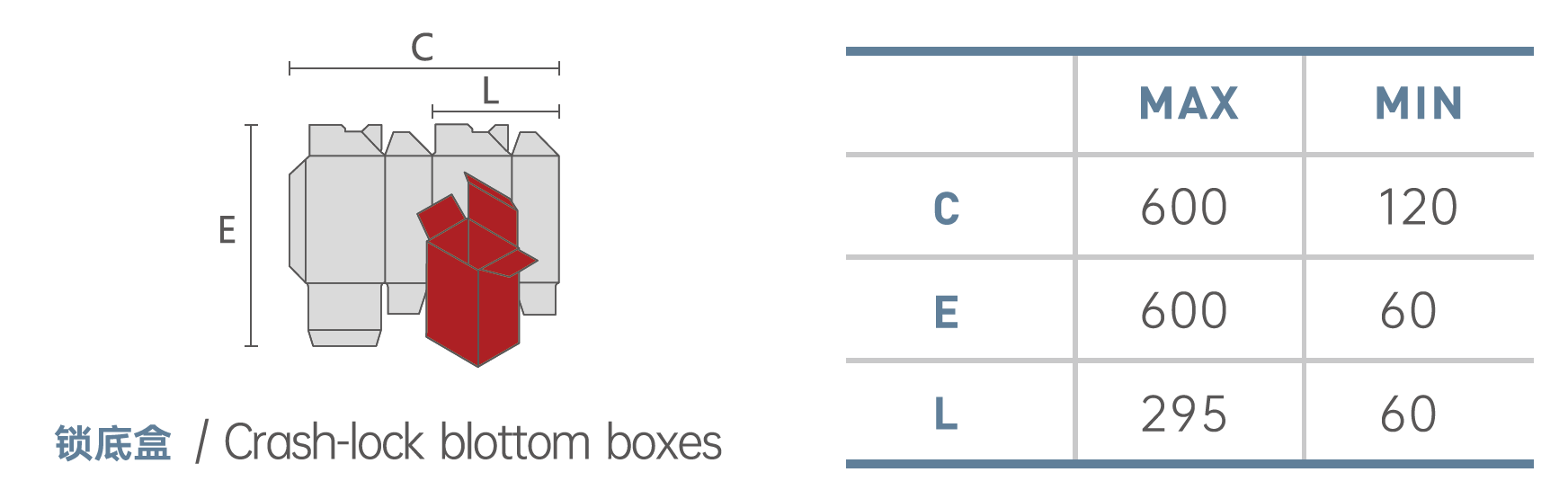

Blank Sizes |

Application |