Features

MODEL | TCut 170 |

Die cutting Type | Single sheet (Lower part is movable,upper part is fixed) |

Max.paper Size | 1700×1260mm |

Min.paper Size | 650×500mm |

Max.die Cutting Size | 1680×1240mm |

Max.die Cutting Pressure | 300N/m² |

Paper Range | Corrugated board 1-8mm |

Max.die Cutting Speed | 5000Sheets/h |

Total Power | 35Kw |

Total Weight | 25T |

Dimensions | 11000×5040×2400mm |

A.Feeding Unit

Featuring a uniquely designed Taiwan-imported paper feed unit with powerful suction, it ensures smooth, stable,and precise paper feeding. The feeding speed can be freely adjusted according to production needs, enabling flat and stable paper stacking and conveying. Paper stacking height is automatically monitored by photoelectric control, ensuring consistently stable stacking and smooth paper transport. |

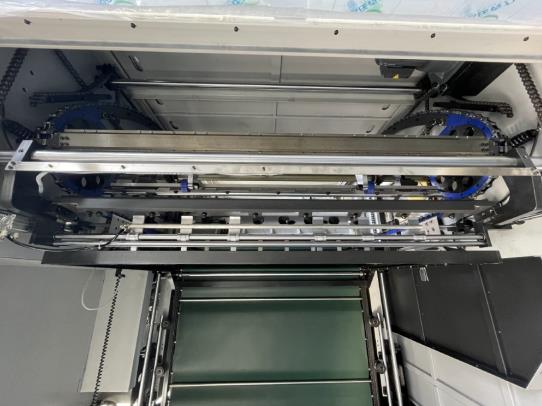

B.Conveying Unit

Equipped with quality high-wear-resistant conveyor belts, paper pressing bristle wheel, and rubber wheels that adapt to backing plates of varying thicknesses. Equipped with advanced phase regulator for regulation of sheet feed timing without stopping the machine With unique deceleration mechanism, ensuring precise positioning of the backing plate at the front gauge. The flat front edges ensure high die-cutting accuracy. |

C.Die Cutting Unit

The die-cutting unit is equipped with an operational safety door mechanism and a safety locking system for die plate frame . Equipped with full-path sheet separation detection monitoring throughout the entire paper transport route. Central positioning system for the die plate frame. |

D.Automatic pile lifting platform of Delivery Unit

With the front, rear, and side alignment devices, the die-cut products can be automatically and neatly stacked. |

E.Control Panel

All electrical components are from world famous brand. Such as Mistubishi PLC, Simens main motor, Yaskawa inverter, Omron relay and Schneider contactor. |