Benefits of Centralized Vacuum Pump and blower System:

l Centralized gas supply significantly improves the utilization rate of each gas supply unit, enhancing operational efficiency. Compared to the previous one-to-one air pump pairing, it reduces the total power consumption of operating equipment, achieving energy savings of up to 50%-60%.

l Reduced heat load in production areas: Printing plants generally feature central air conditioning systems. For every 10KW reduction in heat load, the AC system's power consumption decreases by 1.5KW.

The centralized system replaces rotary vane vacuum pumps, eliminating the oil mist, carbon dust, and heat generated by original pumps during operation. Workshop noise decreases by 5-8dB, and ambient temperature drops by 3-5°C, substantially improving the working environment for employees.

l With significantly fewer centralized supply units compared to the original hundreds of air pumps, daily equipment management and maintenance are reduced. This greatly alleviates administrative workloads while lowering maintenance and operational costs.

Before | After |

|  |

|  |

|  |

Features

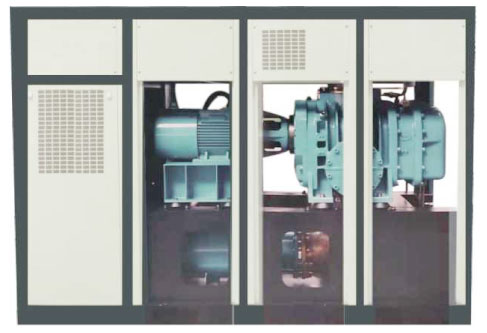

Screw Vacuum Pump

1. Smart Display 3. High-Efficiency Permanent Magnet Synchronous Motor 5. High-Efficiency Coupling 7. High-Precision Oil-Gas Separator 9. Stainless Steel Exhaust Pipe

| 2. Motor Independent Cooling System 4. Direct-Connected Integrated Drive 6. Air Intake Control System 8. High-Precision Intake Acoustic System 10. Extra-Large Screw Vacuum Main Unit |

Screw Blower

The world-class energy efficiency of the oil-free screw blower is primarily attributed to its cutting-edge technology. Other key features ensuring higher efficiency and greater reliability include the integrated gearbox, lubrication oil system, and innovative design (a plug-and-play solution incorporating all individual components).

Project Advantages

1. Adoption of new first-tier brand vacuum pump systems to replace existing outdated equipment.

(1) Main vacuum pump units feature Tornado brand; motors use Saifu or Jiangtian brands—quality rivaling top global brands like Sullair (US) and Atlas Copco. Inverters utilize the reputable INOVANCE brand, offering superior stability over other domestic brands.

(2) Our vacuum pumps deliver rapid pumping speed, low operational power consumption, precision engineering, and minimal noise. Configured with premium components, they outperform competitors in any setting, at any time, in head-to-head comparisons. Designed for a service life exceeding 15 years.

2. Optimized vacuum pipeline system reducing pressure loss and improving air quality.

3. Advantages of Vacuum Pump Energy-Saving Retrofit:

(1) The most cost-effective solution for enterprise technological upgrades, reducing energy consumption and enhancing product competitiveness.

(2) An internationally leading market model for achieving energy conservation and emissions reduction.

(3) ROI originates from the difference in electricity consumption (kWh) per cubic meter of vacuum generated before vs. after retrofit—directly translating to energy cost savings.

(4) The energy savings generated by the retrofit equate to reduced production costs and maximized profits for your company.

(5) Implementing energy-saving vacuum pumps not only lowers production costs but also reduces workshop temperatures, boosts production efficiency, improves product quality, and accelerates enterprise development.

Project Cases

Custom energy-saving retrofits: Contact us for a detailed plan.